Flow meters are vital instruments in modern beverage production, allowing precise measurement of liquid flow in bottle filling machines. Accurate flow measurement ensures product consistency, minimizes waste, and increases production efficiency. This guide covers what flow meters are, which liquids require them, popular brands, and reference prices.

What is a Flow Meter?

A flow meter is a device used to measure the volume or mass of liquid passing through a pipe over time.

Key points:

- Measures volume flow (m³/h, L/min) or mass flow (kg/h, t/h).

- Works with liquids, gases, and high-viscosity fluids.

- In bottle filling machines, flow meters control each bottle’s volume precisely.

When it comes to bottle filling machines, flow meters are chosen based on the liquid type, viscosity, and accuracy requirements. The most commonly used types include:

Electromagnetic (EM) Flow Meters

- Best for: Water, juice, milk

- Pros: No moving parts, high accuracy, easy to clean

- Use: Standard beverage filling lines

Turbine Flow Meters

- Best for: Low-viscosity, clean liquids

- Pros: Simple, cost-effective

- Limitations: Mechanical wear

- Use: Low-speed filling

Coriolis (Mass) Flow Meters

- Best for: High-value liquids, alcoholic beverages

- Pros: Direct mass measurement, very precise

- Limitations: Higher cost

- Use: Premium or high-precision filling

Positive Displacement (Volumetric) Flow Meters

- Best for: Oils, viscous liquids

- Pros: Stable accuracy, handles thick liquids

- Use: Oil and viscous beverage filling

The choice of flow meter depends on the liquid type, required precision, and production speed. Electromagnetic meters dominate beverage lines, while Coriolis and volumetric meters are used for high-value or viscous liquids.

Which Liquids Require Flow Meters?

Not all liquids are best suited for flow meter filling. Selection depends on viscosity, presence of bubbles, and value of the liquid.

2.1 Recommended Flow Meter Liquids

- Water – High-end mineral water

- Non-carbonated soft drinks – tea, energy drinks, functional beverages

- Non-pulp fruit juices

- Low-viscosity milk & plant-based drinks

Liquids Recommended for Flow Meter Filling

| Liquid Type | Reason for Flow Meter Use |

|---|---|

| Water | High-end mineral water |

| Non-carbonated soft drinks | Low viscosity, fast filling |

| Non-pulp fruit juices | No particle interference |

| Milk & plant-based drinks | Continuous flow, hygienic filling |

2.2 Alcoholic Beverages

- Non-carbonated alcohol (vodka, whiskey, red/white wine) → strongly recommended

- Carbonated beer or champagne → not suitable; use level control or pressurized filling instead

| Alcohol Beverage Type | Carbonation | Flow Meter Recommended | Industry Standard Filling Method |

|---|---|---|---|

| Spirits (e.g., Vodka, Whiskey) | No | Strongly Recommended | Flow Meter Filling |

| Red/White Wine | No | Recommended | Flow Meter Filling |

| Fruit Wine / Mixed Drinks | No | Recommended | Flow Meter Filling |

| Beer | Yes | Not Recommended | Pressurized / Level-Controlled Filling |

| Champagne | Yes | Not Recommended | Pressurized Filling |

2.3 NAVAN Beverage Machinery Flow Meter Selection Guide

| Liquid Type | Recommended Flow Meter Type | Typical Application / Notes |

|---|---|---|

| Water / Purified Water / Mineral Water | Electromagnetic Flow Meter | High-speed filling, high accuracy, easy CIP cleaning |

| Non-Carbonated Soft Drinks (Tea, Juice, Functional Drinks) | Electromagnetic Flow Meter | Low viscosity, suitable for fast continuous filling |

| Milk / Plant-Based Drinks | Electromagnetic Flow Meter | Hygienic filling, moderate viscosity, accurate volume control |

| Non-Carbonated Alcohol (Vodka, Whiskey, Red/White Wine, Fruit Wine, Mixed Drinks) | Electromagnetic or Coriolis Mass Flow Meter | High-value liquids, precise filling, prevent overfill |

| Carbonated Alcohol (Beer, Champagne) | Not Recommended | Use pressurized / level-controlled filling instead |

| Fruit Pulp Juice / Drinks with Particles | Positive Displacement (Volumetric) or Piston Filling | Avoid flow meter clogging, handle particles safely |

| Oil / High Viscosity Liquids | Positive Displacement (Volumetric) Flow Meter | Accurate filling for viscous fluids, moderate speed |

| High-Value Concentrates / Additives | Coriolis Mass Flow Meter | Extremely high accuracy, direct mass measurement |

Popular Flow Meter Brands

Flow meters are offered by international and Chinese manufacturers. Selection depends on accuracy requirements and budget.

International Top Brands:

- Endress+Hauser (Switzerland) – electromagnetic, Coriolis

- Siemens (Germany) – electromagnetic, ultrasonic

- Emerson / Micro Motion (USA) – Coriolis mass flow

Chinese Brands:

- CIC / ChuanYi (川仪) – electromagnetic

- Kaifeng Instrument – electromagnetic

- Shanghai Kent – electromagnetic

Flow Meter Brand & Use in Filling Machines

| Brand | Type | Typical Application | Price Range (USD) |

|---|---|---|---|

| Endress+Hauser | EM, Coriolis | High-end beverages | 1,500 – 3,500 |

| Siemens | EM, Ultrasonic | Beverage lines | 1,200 – 2,500 |

| Emerson | Coriolis | High-value liquids | 3,500 – 8,000 |

| CIC | EM | Cost-effective filling | 300 – 800 |

Flow Meter Reference Prices

- Electromagnetic flow meters: USD 300 – 3,500

- Coriolis mass flow meters: USD 3,500 – 8,000+

- Volumetric flow meters: USD 400 – 2,500

- Turbine flow meters: USD 200 – 800

Flow Meter Price by Type

| Type | Typical Price (USD) | Notes |

|---|---|---|

| Electromagnetic | 300 – 3,500 | Most common for beverage filling |

| Coriolis | 3,500 – 8,000+ | High-precision, high-value liquids |

| Volumetric | 400 – 2,500 | For oils & viscous liquids |

| Turbine | 200 – 800 | Low-viscosity liquids, less common now |

When Placed in the Context of a Complete Filling Machine, It’s Easier for Customers to Understand

Example: 12-Head Flow Meter Filling Machine

| Flow Meter Configuration | Flow Meter Cost (USD) |

|---|---|

| Domestic Electromagnetic Flow Meters | 3,600 – 9,600 |

| International Brand Electromagnetic Flow Meters | 18,000 – 36,000 |

| Coriolis Mass Flow Meters | 42,000 – 96,000 |

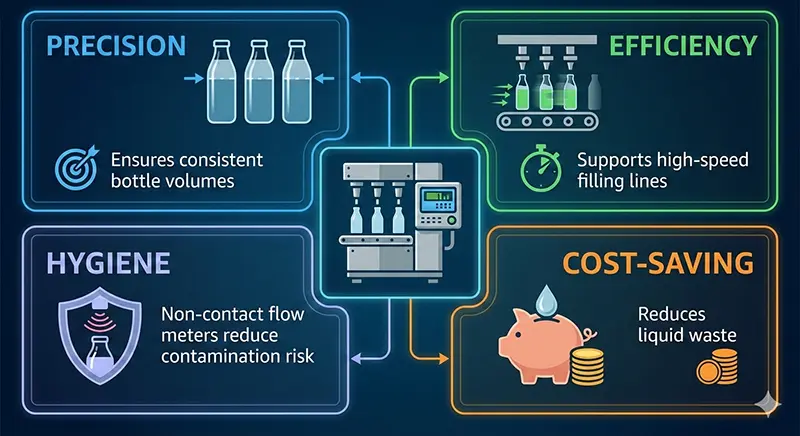

Why Flow Meters are Important for Bottle Filling Machine Manufacturers

- Precision: Ensures consistent bottle volumes

- Efficiency: Supports high-speed filling lines

- Hygiene: Non-contact flow meters reduce contamination risk

- Cost-saving: Reduces liquid waste

Flow meters are essential components in modern bottle filling machines, especially for beverages like water, juice, milk, and non-carbonated alcohol. Choosing the right brand, type, and configuration ensures accuracy, efficiency, and cost-effectiveness.

Contact our team to choose the best flow meter solution for your bottle filling machine.