The XGF 14-12-5 is an efficient water bottle filling machine integrating rinsing, filling, and capping. Built with SUS304 stainless steel, this bottle filling machine delivers 5000 BPH.

Select product requirements by clicking.

This water bottle filling machine combines washing, filling, and capping, significantly reducing the factory footprint and labor costs.

Whether you are producing 100ml or 2000ml sizes, this water bottle filling machine adapts easily to different PET bottle diameters and heights.

To ensure the highest water quality, every contact part of the water bottle filling machine is constructed from high-grade 304 stainless steel.

Powered by a 3.5KW motor, this water bottle filling machine uses advanced frequency control to maintain stable performance during high-speed runs.

This versatile water bottle filling machine is specifically designed for non-carbonated, low-viscosity liquids:

The rinsing section of the water bottle filling machine features 14 stainless steel grippers. These grippers flip the bottles to allow high-pressure internal spraying, ensuring the bottles are sterile before reaching the next stage.

Equipped with 12 specialized valves, this machine utilizes gravity filling technology. It ensures consistent liquid levels across all bottles and prevents any dripping or wastage during operation.

The final stage of the filling machine involves 5 constant-torque capping heads. This system guarantees a leak-proof seal for every plastic screw cap, maintaining the freshness of the bottled water.

The XGF 14-12-5 is a professional bottle filling machine designed for efficiency and hygiene. This 3-in-1 monoblock system integrates bottle rinsing, liquid filling, and screw capping into one automated process. Built with premium SUS304 stainless steel, this bottle filling machine delivers a stable 5000 BPH capacity. Featuring 14 rinsing, 12 filling, and 5 capping heads, it is the ideal solution for PET bottles from 100ml to 2000ml in modern drinking water plants.

| Model | XGF 14-12-5 |

|---|---|

| Production Capacity (500ml) | 5000 BPH |

| Suitable Bottle Specification | Volume: 100–2000ml Diameter: φ50–100mm Height: 150–340mm Volume: 100–2000ml Diameter: φ50–115mm Height: 150–350mm |

| Bottle Neck / Cap Style | Plastic Screw Cap φ20–50mm |

| Main Power (KW) | 3.5 |

| Power Supply | Voltage: 220V–480V / 3 Phase / Frequency:50Hz or 60Hz or your requirement |

| Overall Dimensions (mm) | 2050*1800*2400 |

| Weight (kg) | 2500 kg |

We provide complete turnkey solutions for mineral water production lines, including

design, manufacturing, installation, commissioning, and training.

If the video does not display, please refresh the page or visit our YouTube channel.

This video showcases the complete working process of the 14-12-5 water bottling machine. If you are interested, we can calculate the following data to help you reduce costs and improve efficiency:

Click the button below to see the detailed description.

We select the ideal water treatment solution based on your water source analysis and required water quality—helping you reduce material usage and maintenance costs.

Our advanced purification systems turn raw water into premium pure water, mineral water, and drinking water with consistent quality. From groundwater and mountain springs to rivers, wells, and lakes, our technology ensures reliable treatment across diverse water sources.

Our PET bottle blowing machine is designed for producing high-quality PET plastic containers and bottles. It is widely used for manufacturing carbonated drink bottles, mineral water bottles, oil bottles, pesticide bottles, cosmetics bottles, wide-mouth jars, and more.

With our fully automatic blow molding system, you can easily produce PET bottles in a wide range of shapes and specifications with high efficiency and consistent quality.

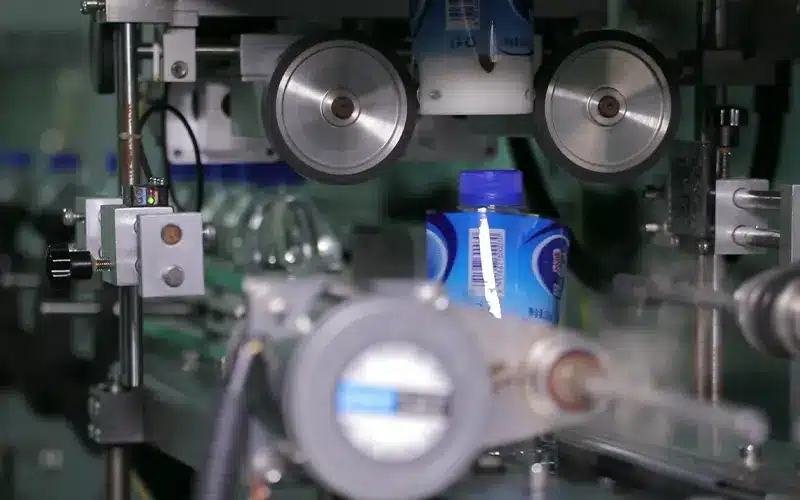

This integrated machine combines washing, filling, and capping functions in a single unit. Its spiral design significantly enhances production speed.

Bottle size adjustment is simple and quick, allowing format changes to be completed within 30 minutes.

The entire machine is controlled by an advanced PLC system, with critical electrical components from internationally renowned brands, ensuring reliable and stable operation.

The conveyor belt, dryer, and coding system of the filling machine work in coordination to ensure smooth bottle handling and optimal production efficiency. Bottles are transported precisely along the conveyor belt, thoroughly dried by a high-efficiency dryer to remove residual moisture, and then accurately positioned for coding or filling.

This integrated process minimizes contamination, reduces moisture residue, ensures consistent product quality, and maintains high production speeds.

Navan labeling and sleeving machines feature a unique composite cutter design combined with premium steel materials, ensuring smooth operation while doubling cutter lifespan.

Their simple center-guide positioning design allows users to easily change specifications with straightforward operation. The first conveyor belt is driven by a brushless DC motor, featuring a well-structured design that is easy to maintain and delivers reliable performance.

This machine is specifically designed for fully automated packaging lines handling products such as beer, beverages, purified water, juice, and dairy products.

It automates the entire process, including bottle conveying and alignment, film wrapping, sealing and cutting, shrinking, cooling, and molding.

The system employs advanced constant-temperature film heat-sealing technology, ensuring clear, strong, and reliable sealing.

The palletizer automatically stacks packaged products (such as cartons, bags, or drums) onto designated empty pallets according to preset sequences.

This mechanized process simplifies product handling and transportation, improving overall production efficiency.

Additionally, interlayer sheets can be added to enhance the stability of each stacked layer. The equipment is designed with flexibility, allowing adjustments to meet various palletizing requirements based on different production needs and configurations.

Navan Machine, Since 2010s, is a professional manufacturer specializing in customized water filling machine. With more than a decade of experience, we have proudly served customers in 42 countries and regions worldwide.

No middlemen – preferential terms and reliable partnerships.

Design, manufacturing, delivery, and installation – all handled by the same supplier.

Experience working with over 40 countries.

Provides components and technical support, with rapid delivery.

The right capacity depends on your factory size, market demand, and budget. For small to medium operations, 2,000-12,000 BPH is recommended. For large-scale production, 12,000-24,000 BPH models are suitable. We can provide a detailed capacity analysis based on your specific requirements.

We implement strict QC procedures, including machining accuracy checks, assembly precision inspection, sampling of electrical components, and FAT & SAT testing to guarantee reliable machine performance.

Standard delivery time is 25-60 days depending on configuration and customization requirements. Standard models can be delivered in 25-35 days, while customized turnkey solutions may take 45-60 days.

We offer 24/7 online technical support, on-site installation and commissioning, operator training, and long-term spare parts supply.

Standard purchased parts: shipped within 24 hours by air express.

Non-standard parts: shipped within 48 hours or technical drawings provided for local processing.

Urgent cases: manual delivery can be arranged.

Yes, we provide comprehensive training for your staff both at our factory and on-site after installation. The training covers operation, maintenance, troubleshooting, and safety procedures. We also provide detailed operation manuals and video tutorials in multiple languages.

Fill in the form below and our sales/engineering team will contact you with a tailored solution, machine configuration, and pricing within 24 hours.

Company Name: Zhangjiagang Navan Industrial Co.,Ltd

Contact Email: info@navan-machine.com

Navan Machine is committed to protecting your privacy. This Privacy Policy explains how we collect, use, disclose, and protect your personal information, especially in compliance with the General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA).

We may collect the following personal data when you visit our website or contact us:

We do not collect or store sensitive personal information such as your financial details.

We collect your data for the following purposes:

We will never sell your personal data to third parties.

We may use cookies or similar tools to track how users interact with our site. You can accept or reject cookies when prompted, and manage them in your browser settings.

To exercise your rights, please contact us at info@navanmachine.com.

We store your data securely and restrict access to authorized personnel only. We implement industry-standard security measures to prevent unauthorized access, disclosure, or loss.

We may share your information with:

We do not sell or rent your data to third parties.

As a China-based company serving global customers, your data may be transferred and stored in other countries. We take steps to ensure all transfers are made with adequate data protection measures.

We may update this Privacy Policy from time to time. The latest version will always be available on our website, and any significant changes will be clearly notified.

If you have any questions or requests regarding this Privacy Policy, your rights, or your data, please contact us:

📧 Email: info@navan-machine.com

🏢 Company: Zhangjiagang Navan Industrial Co.,Ltd

📍 Address: Room 9D ,Henglong Mansion, No.50 Renmin Middle Road, Yangshe Town, Zhangjiagang City, Jiangsu Province. China

Company Name: Zhangjiagang Navan Industrial Co.,Ltd

By accessing and using this website, you agree to comply with and be bound by the following Terms of Use. If you do not agree to these terms, please do not use our website.

This website is intended to provide information about our products and services. You may browse and submit inquiries for business purposes only. Any misuse of content or systems is strictly prohibited.

All content on this site—including text, images, logos, videos, and product information—is the property of Navan Machine Co., Ltd. or its licensors. You may not copy, reproduce, or distribute any content without written permission.

We strive to provide accurate product descriptions, specifications, and pricing, but we do not guarantee that all information is complete or error-free. Navan Machine reserves the right to modify content without prior notice.

If you submit a form, message, or email through this website, you agree that:

This site may contain links to third-party websites. We are not responsible for their content, accuracy, or privacy practices. Use them at your own risk.

Navan Machine shall not be held liable for any direct, indirect, or incidental damages resulting from your use of this website or any linked content.

We reserve the right to update or modify these Terms of Use at any time. Continued use of the site after changes implies your acceptance of the updated terms.

These terms shall be governed by and interpreted in accordance with the laws of the People’s Republic of China.

If you have questions about these Terms of Use, please contact us:

info@navan-machine.com

Our website uses cookies to enhance your browsing experience, provide personalized content, and analyze site traffic. This Cookie Policy explains what cookies are, how we use them, and your choices regarding their use.

Cookies are small text files stored on your device by your browser. They help websites remember your preferences, login information, and provide a better overall experience.

We use cookies for the following purposes:

Some cookies may be set by third-party services, such as analytics providers or social media platforms. These cookies help us analyze traffic, improve our services, and provide social media features.

You can manage or disable cookies through your browser settings. Please note that blocking certain cookies may affect the functionality of the website or your user experience.

We may update this Cookie Policy from time to time. Any changes will be posted on this page with an updated “Last Updated” date.

Last Updated: September 2025