Our water bottling line with a capacity of 36,000 bottles per hour (500ml PET) is designed for high-efficiency production, delivering precision filling, hygienic standards, and cost-effectiveness. This case study highlights how the system performs in real beverage factories, offering insights into automation, packaging, and long-term ROI.

Why Do Beverage Companies Need a High-Capacity Water Bottling Line?

In today’s competitive beverage industry, speed and quality determine success. A water bottling line ensures consistent filling, reduces downtime, and minimizes waste. For companies scaling up to large-scale production, investing in an automatic water bottle filling machine is the key to meeting consumer demand while keeping costs under control.

How Does the 36000BPH Water Bottling Line Work?

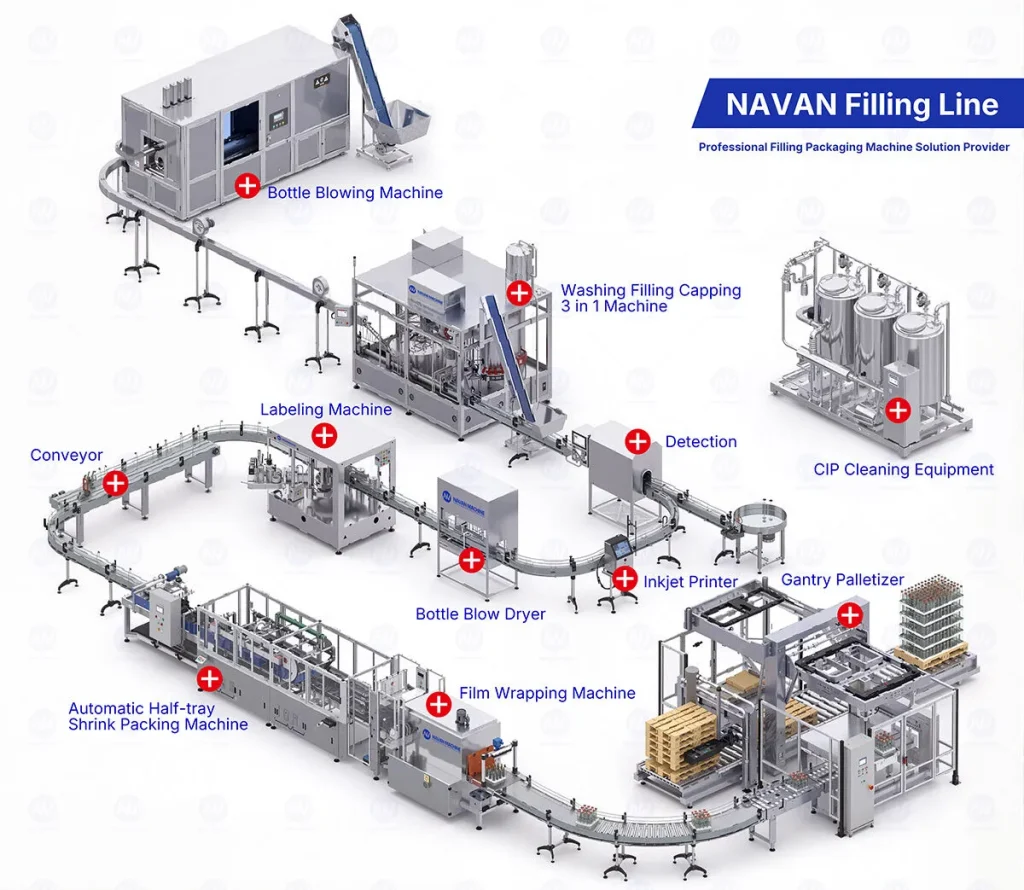

The automatic water bottling machine integrates washing, filling, capping, and packaging into one streamlined automatic water filling production line.

Key Features of the System

- Washing Unit: 18 rinsing heads with stainless steel construction for hygiene.

- Filling Unit: 18 filling valves ensuring accurate volume and no spillage.

- Capping Unit: 6 high-speed capping heads with torque control.

- Automatic Packing: Integrated automatic water bottle packing machine for shrink wrapping or carton packing.

- Smart Controls: PLC system with touch-screen monitoring.

Case Study – 500ml PET Bottle Water Bottling Line in Operation

One of our clients in Eastern Europe installed this automatic water bottling plant in 2024. After 3 months of operation:

- Capacity: 36,000 bottles/hour (500ml PET water bottles)

- Efficiency: 98% uptime with minimal maintenance

- Labor Reduction: From 12 workers to 5 operators due to automation

- ROI: Reached payback within 18 months

Comparison – Traditional Line vs. Automatic Water Bottling Line

| Feature | Traditional Line | Automatic Water Bottling Line (36,000BPH) |

|---|---|---|

| Production Speed | 8,000–12,000 BPH | 36,000 BPH |

| Labor Requirement | 10–15 workers | 4–6 workers |

| Energy Consumption | High | Optimized with energy-saving motors |

| Maintenance | Frequent | Low, with self-cleaning options |

| ROI | 3–5 years | 1.5–2 years |

Advantages of Our Automatic Water Bottle Filling System

- High Efficiency: Up to 36,000 BPH with consistent performance

- Hygienic Design: Stainless steel contact parts, CIP cleaning system

- Flexible Packaging: Compatible with PET bottles from 200ml–2L

- Cost-Effective: Lower labor and maintenance costs

- Scalable: Suitable for small plants and large automatic water bottling plants

Frequently Asked Questions (FAQ)

Q1: What is the price of an automatic water filling machine?

The automatic water filling machine price varies by capacity, configuration, and packaging requirements, typically ranging from $80,000 to $500,000.

Q2: Can the water bottling line handle different bottle sizes?

Yes, the system is flexible and supports PET bottles from 200ml to 2L with quick changeover parts.

Q3: How long does installation take?

On average, installation and operator training take 30–45 days depending on plant layout.

Q4: Is the system suitable for mineral water and purified water?

Yes, the automatic water bottling machine can process both mineral and purified water with precise quality control.

Q5: What after-sales support is provided?

We offer 24/7 remote technical support, spare parts, and on-site service when needed.

External Resources & References

- World Health Organization – Guidelines for Drinking Water Quality

- Beverage Industry Insights – Bottled Water Market Trends

Related Solutions from Navan Machine

Conclusion – Invest in a High-Speed Water Bottling Line Today

The 36000BPH 500ml PET bottle water bottling line offers unmatched efficiency, automation, and reliability for growing beverage brands. Whether you are scaling up or optimizing existing operations, this automatic water filling production line ensures cost savings and market competitiveness.

📧 Ready to upgrade your factory? Contact us today to get a personalized quote for your automatic water bottling plant!